- solutions

- industries

- about us

- resources

Client Resources

Unlocking Low-Carbon Battery Manufacturing in the Nordics

By Dr. Joris Šimaitis, Haley McKercher

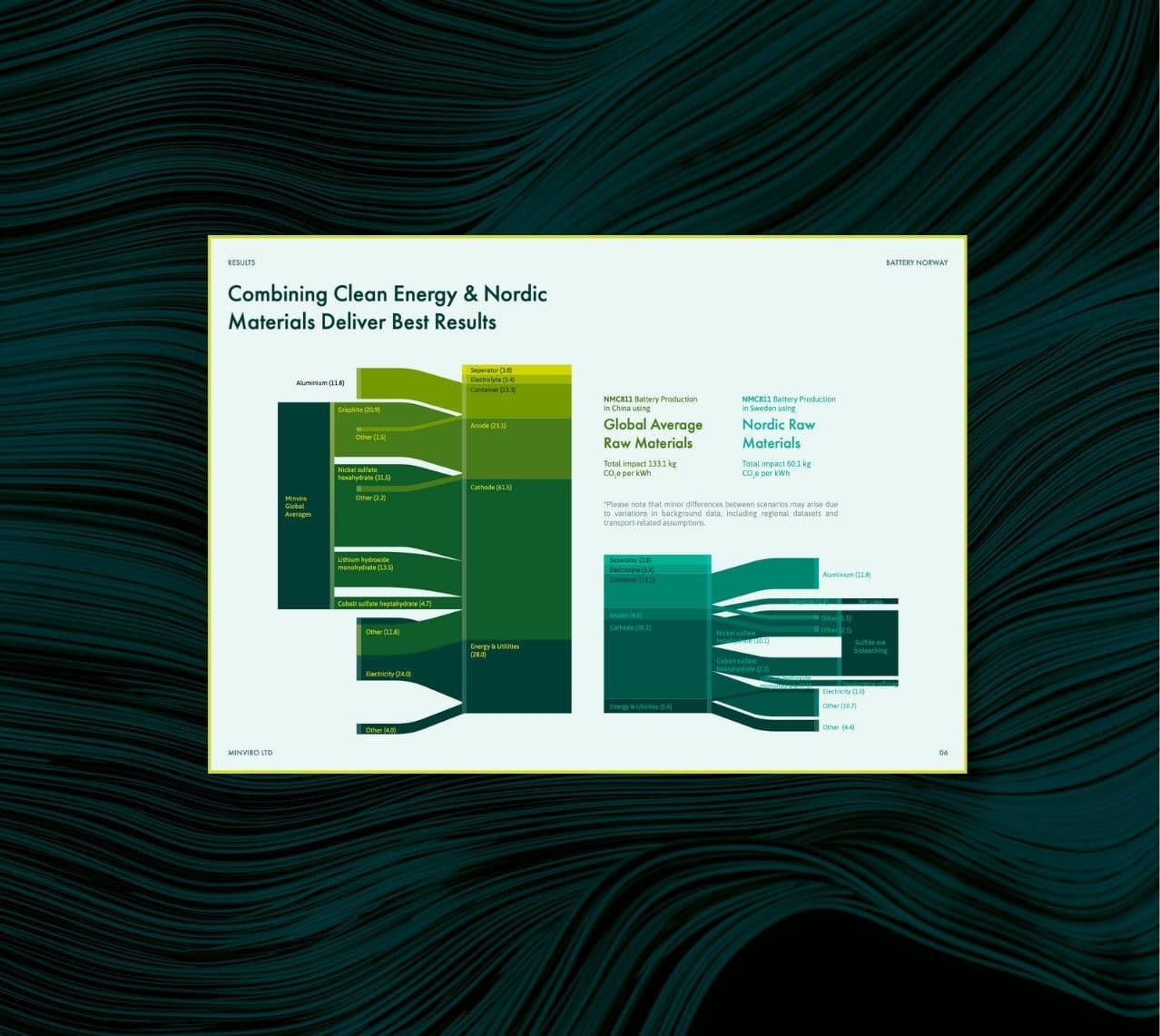

This new Carbon Footprint of Product (CFP) study, conducted by Minviro for Battery Norway with support from the Nordic Council of Ministers, explores how Nordic raw materials and renewable energy can drive significant reductions in battery carbon footprints. By modelling NMC811 and LFP chemistries, the study shows up to 85% lower climate impacts compared to global averages, highlighting the region’s strategic advantage in building a low-carbon, resilient battery supply chain.

Download

The outline

Reducing Battery Carbon Footprints through Nordic Innovation and Collaboration

By modelling Nordic value chains and renewable energy use, it highlights how material sourcing choices can substantially reduce battery production emissions and support EU regulatory and industry decarbonisation goals. If you are interested in learning more about the full technical report please contact Battery Norway directly.

This study examines the carbon footprint of key battery materials, including nickel sulfate, cobalt sulfate, lithium hydroxide, and synthetic graphite, as well as LFP and NMC811 battery chemistries.

How can regional sourcing and clean energy reshape battery carbon footprints?

Battery manufacturing isn’t just about where it happens, it’s about how and with what. This report explores how Nordic raw material routes and renewable energy systems can influence the carbon profile of batteries, offering a different perspective from conventional global supply chains.

Why does the choice of battery chemistry matter?

Chemistries like LFP and NMC811 don’t just differ in performance, they have different materials embedded in them and they carry distinct environmental footprints. The study investigates how these differences play out in a Nordic context, helping decision-makers understand how technology choices shape sustainability strategies.

What role do specific materials play in shaping emissions across the value chain?

Nickel sulfate, cobalt sulfate, lithium hydroxide, and synthetic graphite are at the core of modern batteries. This analysis breaks down their contribution to overall carbon footprints and explores how Nordic production routes could influence future sourcing strategies.

How can recycling fit into a low-carbon battery strategy?

Recycling isn’t just an end-of-life issue, it can be a strategic part of the carbon equation. The report examines how hydrometallurgical recycling and secondary material recovery could contribute to maintaining a lower overall footprint across the value chain.

How can these insights support regulatory and investment decisions?

With EU battery regulation and carbon disclosure requirements accelerating, understanding emissions hotspots is critical. This study provides a structured, ISO-compliant analysis that supports companies in aligning strategy, compliance, and climate ambitions.

download

Get access today

Fill in the form below